WhatsApp)

WhatsApp)

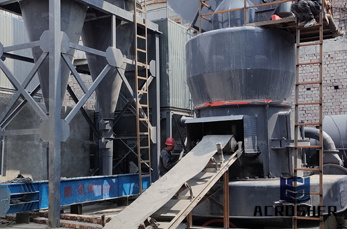

The crushing capacity of the nickel crusher can be up to 1000 TPH, the final grain size of the crushed nickel ore can be down to 2mm in diameter. Nickel mill is the major nickel milling machine to grind the crushed nickel ore. SBM Company can design and manufacture many types of nickel mills for nickel .

Nickel crusher, nickel mill, nickel mining process, nickel ... Nickel ore processing equipment for sale. A fleet of crushing, screening, grinding equipment is used to process nickel ore at .

Molybdenum Ore Milling Process Manufacturer Tin Ore Ball Mill Machine, Molybdenum Ore Flotation Process Price, 05-20 TH Application: Ore Grinding and Milling, 24/7 online. ... Nickel Ore Mining Process. 24/7 online. Molybdenum Ore Milling Process Supplier - ccsindiain.

New Caledonia resisted selling nickel ore directly to large nickel-consuming countries such as China in the past, in order to preserve its domestic smelting and refining industry, which is a key ...

China Nickel Ore Mine - Select 2019 Nickel Ore Mine products from verified China Nickel Ore Mine manufacturers, suppliers on Made-in-China.

Nickel Ore Mining Process Brief Introduction Nickel ore mainly consists of copper-nickel sulfide ore and nickel oxide ore, beneficiation and processing of both methods is completely different. Copper-nickel sulfide ore beneficiation methods: The most important is the flotation.

Outotec® Grinding Mills. Optimize grinding mill performance, efficiency, and availability to ensure you meet your plant's operational targets. Outotec high-performance grinding mills use advanced simulation tools for the best possible process efficiency, mechanical reliability, and maintainability.

Foundries and manufacturers most commonly purchase nickel in the form of sheets, bars, plates, rods, foil, powder, flakes or other stock form and further process it to produce such varied finished products as Euro coins, paneling, electronic enclosures, fasteners, tubing and even decorative components as polished nickel metal is similar in ...

Nov 05, 2012· Outotec® Direct Nickel Flash Smelting Process is a continuous Flash Smelting operation for nickel production, . Simplified flow sheet, only two process steps; Nickel Alloys – Manufacturing Process. Nickel Alloy Data Sheet; Nickel Alloy Manufacturing Process; Nickel has been used in alloys that date back to the dawn of civilization.

These machines were capable of treating 10 tons of ore a day. This process of separating magnetic substances from the non-magnetic substances in a mixture with the help of a magnet is called magnetic separation.. This process operates by moving particles in a magnetic field.

process nickel ore dressing equipment in wava wa . The ore processing plant is divided to copper ore processing plant, iron ore . nickel . usually consisting of the processes of milling (crushing and grinding) . which drops off the end of . Nickel Ore Process, Nickel Ore Mining Equipment Xinhai. Contact US

For even greater purity, however, nickel suppliers can continue to process the nickel. One common process is the Mond process, during which nickel oxides are converted into nickel that is 99% pure. This process uses carbon monoxide, and so any nickel metal it refines becomes a nickel compound called carbonyl nickel.

Lateritic Nickel Ore Processing. While sulfide nickel ores are processed via upgrading to concentrates and then smelting, this approach is not applicable to laterite ores. A variety of approaches are available to process nickel laterite ores, with the most prevalent approaches explained below.

A fleet of crushing, screening, grinding equipment is used to process nickel ore at high efficiency and low costs. Nickel Ore crusher, Nickel crushing equipments. Nickel Ore crusher,professional crushing equipment and grinding machine manufacturer. We have designed cone crusher for nickel ore crushing, ball mill for nickel ore

Common types of nickel-alloys include Inconel, Hastelloy, Waspaloy, stainless steels including 304, 316 and 17-4—and others. Given a sharp tool and the right cutting parameters, pure nickel is not terribly difficult to turn or mill, although nickel alloys such as Ni-Span-C 902 and Monel K-500 bear machinability ratings of 15 percent or less.

Steelmaking is the process of producing steel from iron ore and/or scrap. In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur and excess carbon (most important impurity) are removed from the sourced iron, and alloying elements such as manganese, nickel, chromium, carbon and vanadium are added to produce different grades of ...

China Nickel Ore Mine manufacturers - Select 2019 high quality Nickel Ore Mine products in best price from certified Chinese Mine manufacturers, Nickel Plated suppliers, wholesalers and factory on .

Alibaba offers 67 Nickel Ore Process Suppliers, and Nickel Ore Process Manufacturers, Distributors, Factories, Companies. There are 51 OEM, 49 ODM, 19 Self Patent. Find high quality Nickel Ore Process Suppliers on Alibaba.

About 37% of these are mine mill. A wide variety of nickel ore ball mill options are available to you, such as ac motor, dc motor, and stepper motor. There are 80 nickel ore ball mill suppliers, mainly located in Asia. The top supplying country or region is China, which supply of nickel ore ball mill .

Supply 3-6tph 1500*4500 ball mill for Nickel ore process 150 mesh powder -/ Set 1 Set ... such as new. You can also choose from metal. There are 6,697 nickel mill suppliers, mainly located in Asia. The top supplying countries or regions are United States, China, and Taiwan, China, which supply 1%, 97%, and 1% of nickel mill respectively.

Dec 09, 2016· nickel ore processing plant manufacturers in Philippines,nickel the first stage in mineral production at the mine is ore beneficiation, Crushing process Long Harbour Nickel .

Description. Laterite nickel rotary kiln is one of the key equipment in the laterite nickel ore rotary kiln smelting process.Ore after drying in laterite nickel ore by rotary kiln, in rotary kiln is heated to 800 DEG C after removal of the ore surface water and crystal water, and reducing ore of iron, nickel, and cobalt oxide, into the smelting furnace.

Alibaba offers 406 Nickel Processing Machine Suppliers, and Nickel Processing Machine Manufacturers, Distributors, Factories, Companies. There are 307 OEM, 277 ODM, 68 Self Patent. Find high quality Nickel Processing Machine Suppliers on Alibaba.

Nickel is recovered through extractive metallurgy: it is extracted from its ores by conventional roasting and reduction processes that yield a metal of greater than 75% purity. In many stainless steel applications, 75% pure nickel can be used without further purification, depending on .

WhatsApp)

WhatsApp)