WhatsApp)

WhatsApp)

Dec 20, 2018· Limestone powder (LS) is one of the mineral materials in concrete due to its wide availability and low cost. This paper discusses effects of LS on the workability, setting time, shrinkage, mechanical properties and durability of concrete.

Aug 26, 2016· Locate dolomite powder products, suppliers, Manufacturers, traders & wholesalers around the world, hellotrade limestone powder making process in sri lanka dolomite powder making process.

Limestone Powder. Nordkalk limestone powders are made by grinding the limestone in different mills. Limestone powders are used widely in different applications. It is also used as raw material for making limestone granules with the binder.

The contents of limestone powder for each cement content were 165, 139, 116, and 96 kg/m3 respectively. Fresh performance of self compacting concrete was determined by slump flow, J-ring and ...

limestone powder. Limestone is used in more dairy products than one might think. Limestone is a sedimentary rock, formed by inorganic remains, such as shells .

Limestone is a material of national importance, and resource sterilization can result in a longer haul at a higher cost from quarry to customer. Limestone Production Patterns. Most of the limestone that is mined is crushed for aggregate. The majority of U.S. crushed stone production has come from limestone for at least the last 40 years.

Limestone mill grinds limestone into powder, limestone powder has different specifications: It can be used to produce anhydrous calcium chloride which is the main auxiliary raw material of sodium dichromate production. It is the main raw material of glass & cement production, it also can be used in the areas of building materials and poultry feed.

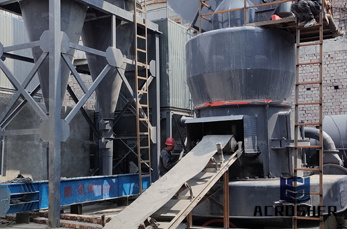

Limestone Powder Production line includes small jaw crusher, bucket elevator, hopper, vibrating feeder, limestone mill, bagging machine, electric control box, etc. 1. Bigger size limestone is crushed by the small rock crusher into smaller size in advance. This is because the max feed size of the limestone mill should be smaller than 30mm. 2.

GMC is one of largest manufacturer of Gypsum in GCC sourcing most of raw materials from Oman itself. GMC also engages in production of Limestone, Marbles, Gypsum boards and blocks.

May 06, 2013· An application of a chemical equilibrium for an industrial system is lime production from limestone. The products which are made from burnt limestone are called lime (ie. quicklime and hydrated lime). Limestone is naturally occurring, and it also consits of minerals in small pieces. Presently, limestone products are used as a crucial part in most industrial processes.

Limestone has numerous uses: as a building material, an essential component of concrete (Portland cement), as aggregate for the base of roads, as white pigment or filler in products such as toothpaste or paints, as a chemical feedstock for the production of lime, as a soil conditioner, or as a popular decorative addition to rock gardens

Production of high-strength lightweight concrete using waste lightweight oil-palm-boiler-clinker and limestone powder. Lee Jin Chai Department of Civil Engineering, Faculty of Engineering, University of Malaya, Kuala Lumpur, ...

Alibaba offers 13,388 limestone powder products. About 28% of these are carbonate, 26% are mine mill, and 7% are lime. A wide variety of limestone powder options are available to you, such as calcium carbonate, raymond mill, and sodium bicarbonate.

Chemical and Physical Properties of Limestone Powder as a Potential Microfiller of Polymer Composites. ... the effects of the amount of resin used for the production of .

Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore. These ingredients, when heated at high temperatures form a rock-like substance that is ground into the fine powder .

Limestone powder processing technological process Phase one: raw material crushing Limestone blocks will be crushed to 15mm-50mm fineness by crusher. Phase two: grinding Lime material will be sent to the storage hopper by the elevator, and than the .

In the steel production process carried out at the Glenbrook plant south of Auckland, large amounts of limestone and lime are needed to remove impurities during the iron ore reduction phase and the steel production phase. The Ōtorohanga region supplies these much-needed ingredients.

The limestone can be directly ground to obtain heavy calcium carbonate. According to the grinding fineness, the limestone can be divided into four different specifications in industry: single fly powder, double fly powder, three fly powder and four fly powder, which are respectively used in various industrial sectors.

Limestone powder (LS) has been widely used in cement-based materials; and reportedly, can influence their properties by filler, nucleation, dilution and chemical effects. The action mechanism of LS mainly depends on its particle size and amount. ... (USGS) in 2017, the world production of Portland cement was approximately 4.2 billion tons .

The major environmental impact of concrete comes from CO₂ emissions during cement production. The main goal of this research was to develop an optimized cement replacement in order to reduce energy consumption and CO₂ emissions. This was tested by incorporating limestone powder in concrete to meet construction specifications. This study utilized limestone powders with different particle ...

Production process. Nordkalk extracts limestone and processes it into crushed and ground limestone, concentrated calcite, and quick and slaked lime. The product range also includes dolomite and wollastonite. Scroll down to explore the production process step-by-step!

Annual production of limestone. Data for the annual production of calcium carbonate are not readily available. Approximately 1 billion tonnes of its two principal ores, limestone and dolomite, are mined annually in the US. Given the relative amounts of lime that is used in different countries, an estimate of worldwide mining of calcium ...

Production. In the lime industry, limestone is a general term for rocks that contain 80% or more of calcium or magnesium carbonates, including marble, chalk, oolite, and marl.Further classification is by composition as high calcium, argillaceous (clayey), silicious, conglomerate, magnesian, dolomite, and other limestones. Uncommon sources of lime include coral, sea shells, calcite and ankerite.

Center for By-Products Utilization LIMESTONE POWDER USE IN CEMENT AND CONCRETE By Tarun R. Naik, Fethullah Canpolat, and Yoon-moon Chun Report No. CBU-2003-31 REP-525 July 2003 A CBU Report Department of Civil Engineering and Mechanics College of Engineering and Applied Science THE UNIVERSITY OF WISCONSIN – MILWAUKEE DRAFT REPORT

WhatsApp)

WhatsApp)