WhatsApp)

WhatsApp)

Oct 21, 2009· Introduction: Milling is the cutting operation that removes metal by feeding the work against a rotating, cutter having single or multiple cutting edges. Flat or curved surfaces of many shapes can be machined by milling with good finish and accuracy. A milling machine may also be used for drilling, slotting, making a circular profile and gear cutting by having suitable attachments.

May 13, 2016· Milling machine is used to machining the metal workpiece by a revolving cutting tool. The milling cutter usually used to cut the metal perpendicular to the tool axis. Milling machine is used to form various types of parts in the industries because it can machine all shape and size work piece.

HOW TO USE FANUC MIRROR FUNCTION ... switch to 0 and power down power up the machine, this should reset machine back to original state prior to the changing of mirror switch. 9. If you have multiple mirrored parties/cavities need to machine, you still can use G52 to shift the

Ending Today at 9:34AM GMT 17m 53s Collection in person Function: Milling. End Mills - Collection of ~50 assorted used cutters and ~15 used reamers. £26.00. ... SINPO 2 AXIS DIGITAL READOUT DRO FOR MILL MILLING MACHINE&LINEAR SCALES FAMOUS. £296.88 (£296.88/Unit) *Job Lot* Metalworking Tools CNC Pull Broaches for Broaching Machine Milling.

Do not use a rotary table without being familiar with its basic functions. Make sure you understand how to use a milling machine before employing the rotary table. Study the functions of the milling machine first, then the rotary table. To avoid injuries, follow the instructions as stated in the guide.

Note that the articles in this section are a bit specialized. Choose the ones that are appropriate to the kind of machine you'll actually be using first, then branch out and see how some of the other machines work for comparison. CNC Mill Cutter Types and How to Use Them. Learn the basics of cutters used with CNC Milling Machines.

TPC Training's Basic Milling Procedures course covers the setup and use of the horizontal milling machine and describes the functions of basic cutters and attachments. The Basic Milling Procedures course covers the setup and use of the horizontal milling machine, and describes the functions of basic cutters and attachments. Uses "hands-on ...

Dec 24, 2009· The principle parts of milling machine are given: Base; The base of the machine is Grey iron casting accurately machined on its top and bottom surface and serves as a foundation member for all the other parts which rest upon it. It carries the column at its one end. In some machines, the bage is hollowed and working as a reservoir for cutting ...

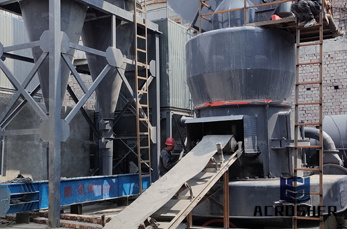

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotati

The function machine metaphor can also aid one in understanding how a function can depend on parameters. Parmameters are additional quantities that influence the behavior of the function. Parmameters are additional quantities that influence the behavior of the function.

– CNC Milling Machine Workholding – CNC Router Workholding – CNC Lathe Workholding . 7. Set Part Zero and Work Offsets. Deliverable: The CNC Machine's 0, 0, 0 coordinate is properly aligned with the desired Part Zero. Any Work Offsets used by the program are properly set up on the machine.

Function: Milling. £24.00 postage. 12 watching. XJ12-300 Mini-Milling Machine MT3 Gear Headed Metric Gas Strut. £649.00. Click & Collect. ... Make offer - Mini Milling Machine Work Table Cross Slide Drilling Press Vise Fixture Set UK. Clamping Kit - 58 Pieces With Step Blocks & .

CNC vertical machining centers (VMCs) remain machine shop staples. These milling machines have vertically oriented spindles that approach workpieces mounted on their table from above and commonly perform 2.5- or 3-axis machining operations. They are less costly than horizontal machining centers ...

Milling Machine Operators job function is to set up, operate, or tend milling or planning machines to mill, plane, shape, groove, or profile metal or plastic work pieces. The Milling Machine Operator removes work pieces from machines, and check to ensure that they conform to specifications, using measuring instruments such as microscopes ...

PROGRAMMING MANUAL for MAZATROL MATRIX (For INTEGREX IV) MAZATROL Program ... Sample program Machines of INTEGREX e-Series Turning machines S1000M3 The milling spindle rotates at 1000 min–1. ... Use the dry run function to check the machine for .

– A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. (milling machine) • Types – Peripheral milling • Slab, slotting, side and straddle milling • Up Milling (Conventional) & down milling (Climb) – Facing milling • Conventional face, Partial face, End, Profile, Pocket & contour ...

Most milling machines have only one spindle, but there are also multi-spindle types. Milling machines with a single spindle can also be equipped with special milling shafts, allowing the simultaneous work of several drills engaged on different surfaces. Types of milling machines

Jul 13, 2017· Milling is the cutting operation that removes metal by feeding the work against a rotating, cutter having single or multiple cutting edges. Flat or curved surfaces of many shapes can be machined by milling with good finish and accuracy. A milling machine may also be .

Everything works and the machine runs pretty smooth. I have not done much with the mill yet. My only issue with the milll is that the spindle is quite high above the carriage and vice. In order to mill a small part using an end mill in a collet you will need to come up with a solution to raise the work piece.

Aug 08, 2017· More Details Contact No.+91 7575075231 Automatic Dhaga Cutting Machine • First time in India. • Two types of machine: 1.Single Head 2. Double Head • Light We...

Mill Machining, Milling Process, Horizontal & Vertical Milling Machines Definition. Milling is a process performed with a machine in which the cutters rotate to remove the material from the work piece present in the direction of the angle with the tool axis. With the help of the milling machines one can perform many operations and functions starting from small objects to large ones.

Milling machines are extremely adaptable. They are typically used to machine level surfaces, yet can likewise create sporadic surfaces. They can likewise be utilized to bore, bore, cut apparatuses, and create openings. The sort of Milling machine ...

Nov 12, 2012· What to look for in a used Bridgeport type milling machine, and demonstration and discussion of the features in a Bridgeport type milling machine by Dale Schafer, Machine.

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations.

WhatsApp)

WhatsApp)