WhatsApp)

WhatsApp)

Jul 02, 2014· analysis of universal joint shaft for rolling mills because this ... DESIGN ANALYSIS OF UNIVERSAL JOINT SHAFT FOR ROLLING MILLS 1. ... this vertical rolling mill stand is fitted with the rolls with grooves and hydraulic screw- down mechanisms. • It has heavy duty construction, a sturdy design, requires low maintenance, has easy operation and ...

rolling mill: see steel steel, alloy of iron, carbon, and small proportions of other elements. Iron contains impurities in the form of silicon, phosphorus, sulfur, and manganese; steelmaking involves the removal of these impurities, known as slag, and the addition of desirable alloying elements.

A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS Dr. Karl Heinrich Schröder

The two high reverse roll which have incorporate a drive mechanism and work is continuously through back- and –forth passed between the rolls. That are usually employed for initial rolling of an ingot. Three high rolling mills or triple roll: triple roll or three rolling mill

Nonlinear dynamic rolling forces in the vertical and horizontal directions are, respectively, established, considering the impact of vertical and horizontal directions vibration of rolls. Then a vertical-horizontal coupling nonlinear vibration dynamic model of rolling mill rolls is proposed, based on the interactions between this dynamic rolling force and mill structure. The amplitude ...

This large lab mill on a base is powered with a 110 volt, 1 HP DC variable speed motor connected to a reducer to achieve 0 to 30 RPM. The separating force of the mill is approximately 20,000 LBS. The mill and drive are mounted on a steel base complete with all electrics and controls. This mill can be equipped with entry and exit tables.

Rolling mill V10 Combo . V10 combo rolling mill is a small size, low cost and one piece cast iron frame makes these mills a good deal.Rolls made of extra- quality steel work for more than 15 years and they are made of special- purpose steel. Rockwell hardness is more than 60.

Hot rolling is a metalworking process that occurs above the recrystallization temperature of the material. After the grains deform during processing, they recrystallize, which maintains an equiaxed microstructure and prevents the metal from work hardening. The starting material is usually large pieces of metal, like semi-finished casting products, such as slabs, blooms, and billets.

Oct 18, 2017· Next type of rolling mill is three high rolling mill. In this type of rolling mills, three rollers are used one over the other in a vertical line. We can pass the ingot between first two rollers ...

shifting, and roll crossing mechanisms. Validation of the static model is provided by comparing results and solution time with large-scale, commercial finite element simulations. In addition to examples with the common 4-high vertical stand rolling mill, application of the presented method to the most complex of rolling mill configurations is

Rolling mill vibration is a worldwide problem, although it has been found that the mill structure defects are the main cause of vibration, but the inhibition measures are difficult to implement. So we discussed the rolling force parameters influence on rolling mill vibration and suppression measures from rolling technology in this article.

Apr 13, 2018· This paper focuses on identifying opportunities to increase mill capacity and modernize existing periodic cold-rolled pipe mills. We provide a comparative analysis of a variety of systems for equilibration of the dynamic forces in the working-stand drive mechanism.

Collars, couplings, cams, clutches, flywheels, shaft ends, spindles and horizontal or vertical shafting are examples of common hazardous rotating mechanisms. The danger increases when bolts, nicks, abrasions and projecting keys or setscrews are exposed on rotating parts. According to 29 CFR 1910.219 (L), these must be made flush or guarded.

Jun 04, 2018· Dangerous Biggest Heavy Duty Lathe Machine Work, Fastest CNC Lathe Machine Modern Technology.

The working roll of the rolling mill is driven by a series of drive mechanisms through a motor. The rolling pieces are processed by two opposite rotating rolls under pressure to produce plastic deformation. The 4-hi rolling mill completes this process by working rolls. The work roll includes two kinds of motion: rotating and moving.

1. Vertical Ring Rolling Mill Vertical Ring Rolling Mill, or VRRM for short, being discussed here, was a machine that was developed in Japan some decades ago, and had a ring-forming roll configuration which was different from the one that is seen with the currently-conventional horizontal (radial/axial) type ring rolling mill.

Jul 12, 2013· Abstract: In the case of a drive arrangement for a rolling mill, comprising at least one drive motor (M), a main gear mechanism (HG), a pinion gear mechanism . Rolling Mill Reducer – Vertical Mill Gearbox: Wind power energy Gearbox: Various .

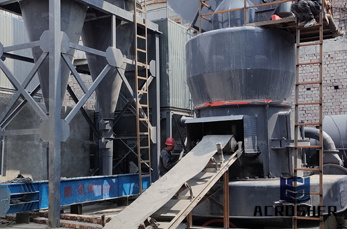

A vertical rolling mill is disclosed wherein a means for driving the mill rolls is comprised of a rigid vertical spindle having universal joints and couplings at either end which is detachably connected to the mill roll at its lower end and connected to a splined driving member at its upper end. The splined driving member consists of two parts.

Jun 13, 1978· BACKGROUND OF THE INVENTION. The present invention relates to a drive mechanism for vertical rolling mills and more particularly it relates to a drive mechanism for vertical rolling mills which itself is provided with a device for mounting a driven coupling on and dismounting it from the neck of a working roll.

A watermill or water mill is a mill that uses hydropower.It is a structure that uses a water wheel or water turbine to drive a mechanical process such as milling (grinding), rolling, or hammering.Such processes are needed in the production of many material goods, including flour, lumber, paper, textiles, and many metal products. These watermills may comprise gristmills, sawmills, paper mills ...

rolling mills and bar-in-coil mills plays a crucial role in the production of high-quality product. Upstream rolling and cooling components of the mill have worked in concert to make a high quality product, with consistent size and coil shape. Now, the coil must be transported for further cooling, compacting and storage or shipment.

Gear systems for hot rolling mills For long products, Eisenbeiss offers the full range of gear systems from the entry mill to the finishing mill. Eisenbeiss pinion gears in horizontal or vertical configurations have been designed to operate in extremely tough environments involving mill .

rolling mill. The efforts are made to access different alternative mechanisms which would be capable to work with the outlet conditions of bar of rolling mill. The bar coming out from the rolling mill is fed to the proposed mechanism for forming the helical coil. The suitable alternatives are discussed.

In the 19th century roller mills were adapted to grist mills before replacing them. The mill used either steel or porcelain rollers. Between the years 1865 and 1872, the Hungarian milling industry upgraded and expanded the use of stone mills combined with roller mills in a process known as Hungarian high milling.

WhatsApp)

WhatsApp)